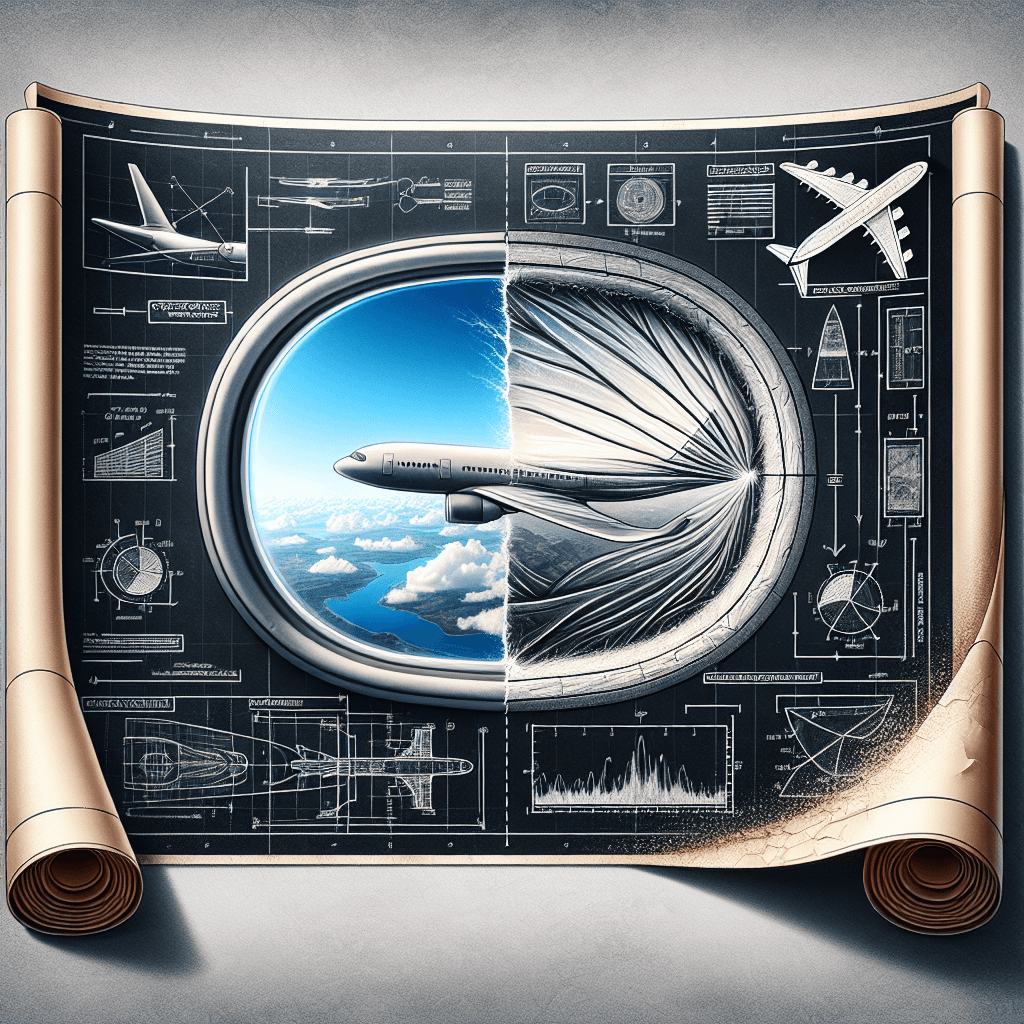

Why are many airplane windows oval instead of square

That smooth curve on your airplane window is more than just a design choice—it's the crucial feature preventing the entire aircraft from cracking apart under the immense pressure of flight.

Too Long; Didn't Read

TLDR: Square windows have sharp corners where stress from air pressure concentrates, which can cause the plane's metal body to crack. Oval windows distribute that stress evenly, making them much safer and preventing the fuselage from breaking apart.

The High-Flying Reason: Why Are Many Airplane Windows Oval Instead of Square?

Have you ever settled into your seat for a flight, looked out the window at the clouds, and wondered about its shape? It's a small detail, but the smooth, rounded corners of an airplane window are far from a simple stylistic choice. They represent a critical piece of engineering born from a tragic history, and they are one of the key reasons you can fly safely at 35,000 feet. This isn't about aesthetics; it’s about physics and survival. This post will explore the crucial engineering principles and historical lessons that made oval windows the industry standard for air travel.

The Pressure to Perform

To understand the window shape, we first need to understand the environment of a commercial flight. At a typical cruising altitude of 30,000 to 40,000 feet, the outside air pressure is incredibly low, and the air is too thin to breathe. To keep passengers and crew safe and comfortable, the aircraft's cabin is pressurized.

Think of the plane's fuselage as a soda can. The air pumped into the cabin creates a much higher pressure inside than outside. This pressure difference, which can be up to 8 pounds per square inch (psi), exerts a constant and immense outward force on the plane's structure, or "skin." The fuselage is designed to handle this stress, but any opening—like a door or a window—creates a potential weak point.

The Problem with Sharp Corners: Stress Concentration

When a material is under pressure, the resulting stress needs to flow smoothly through its structure. A square or rectangular window introduces sharp, 90-degree corners, and this is where the trouble begins.

These corners interrupt the smooth flow of stress, causing it to build up and concentrate at these sharp points. This phenomenon is known as stress concentration. Imagine a river flowing smoothly until it hits a sharp rock. The water swirls violently around the rock's corners. In the same way, stress "piles up" at the corners of a square window, making these points two to three times more stressed than the rest of the fuselage. Over time, this concentrated stress can lead to cracks and material failure.

A Tragic Lesson: The de Havilland Comet

This isn't just a theoretical problem. The aviation industry learned this lesson in the most tragic way possible in the 1950s with the de Havilland Comet. The Comet was the world's first commercial jetliner, a marvel of modern engineering. However, within a year of its introduction, a series of catastrophic in-flight disasters occurred.

- In 1954, BOAC Flight 781 broke apart mid-air over the Mediterranean Sea.

- Just a few months later, South African Airways Flight 201 suffered the same fate.

Intensive investigations, which included recovering wreckage from the seafloor, eventually found the cause. The culprit was metal fatigue. The repeated cycles of pressurizing and depressurizing the cabin on each flight caused microscopic cracks to form at the corners of the Comet's large, square windows. Over dozens of flights, these cracks grew until the fuselage failed, leading to explosive decompression and the complete destruction of the aircraft.

The Superiority of the Oval

The findings from the Comet disasters fundamentally changed aircraft design forever. Engineers realized that by rounding the corners of the window, they could eliminate the points of stress concentration.

An oval or rounded shape allows the pressure-induced stress to flow evenly around the opening without any points to "catch" on and build up. This distribution of force makes the structure significantly stronger and more resistant to the metal fatigue that doomed the Comet. Today, every cutout in a pressurized fuselage, from passenger windows to cargo doors, has rounded corners. It's a simple, elegant, and life-saving solution to a complex physics problem.

Conclusion

The oval shape of an airplane window is a direct result of a crucial lesson in engineering and safety. The immense pressure difference between the inside and outside of an aircraft at cruising altitude places enormous stress on its structure. While square windows create dangerous points of stress concentration at their corners, the smooth curve of an oval allows this stress to flow harmlessly around the opening. The tragic failures of the de Havilland Comet served as a stark reminder of this principle, paving the way for safer aircraft design. So, the next time you fly, take a moment to appreciate your window. That simple curve is a testament to how engineers learn from the past to build a safer future, ensuring your journey is smooth and secure.