Why are some ships deliberately fitted with metal blocks that are designed to be destroyed

It sounds like madness, but these humble metal blocks are designed with a single, vital mission: to sacrifice themselves to the sea, preventing the ship's massive hull from being eaten alive.

Too Long; Didn't Read

TLDR: Those blocks are sacrificial anodes. They are made of a metal that corrodes more easily than the ship's hull. In saltwater, the blocks get destroyed by electrical currents and corrosion on purpose, so the important parts of the ship, like the hull and propeller, are protected. It is much cheaper to replace the blocks than to repair the ship.

The Unsung Heroes of the High Seas: Why Are Some Ships Deliberately Fitted with Metal Blocks Designed to be Destroyed?

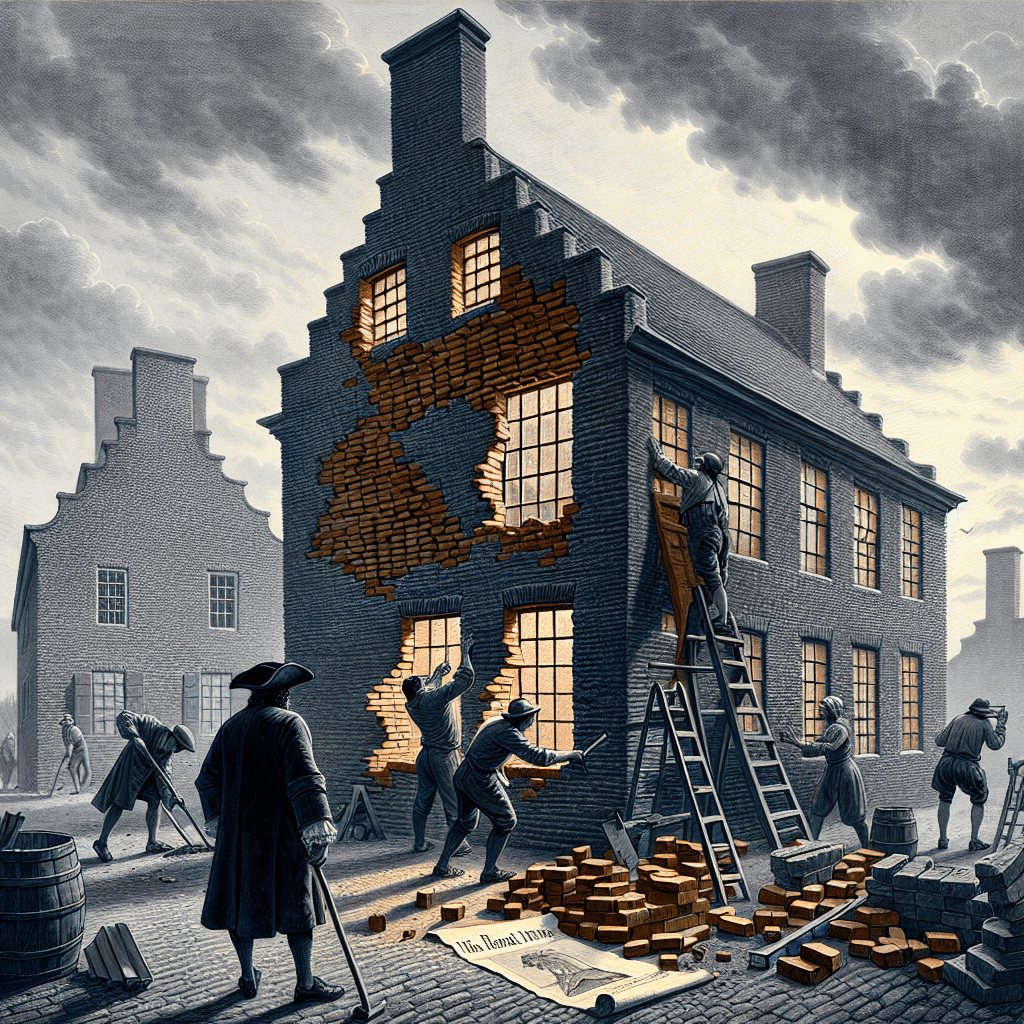

Have you ever looked at a massive ship in dry dock and noticed strange, blocky pieces of metal welded to its hull? It might seem counterintuitive to attach extra components to a carefully engineered vessel, especially ones that look like they are designed to corrode and fall apart. However, these metal blocks are not a design flaw; they are a crucial and ingenious piece of maritime engineering. They are deliberately designed to be destroyed to save the ship itself from a relentless, invisible enemy: galvanic corrosion.

This blog post will dive into the fascinating science behind these self-destructing blocks. We will explore what they are, the chemical reaction they prevent, and why their sacrifice is absolutely essential for keeping ships, from small boats to supertankers, safe and seaworthy.

The Unseen Enemy: Galvanic Corrosion

To understand why these blocks exist, we first need to understand the threat they combat. When two different types of metal are in physical or electrical contact with each other while submerged in an electrolyte (like saltwater), they create a kind of natural battery. This process is called galvanic corrosion.

In this underwater battery, one metal becomes the "anode" and the other becomes the "cathode." The more chemically active metal (the anode) corrodes at an accelerated rate, sacrificing its electrons, while the less active metal (the cathode) is protected. A ship is a perfect environment for this to happen:

- Different Metals: A ship's hull is typically made of steel, while its propeller is often a bronze alloy.

- Electrical Connection: These parts are all connected, forming a complete circuit.

- Electrolyte: The vast ocean of saltwater acts as a powerful electrolyte, facilitating the flow of ions between the metals.

Without intervention, the steel hull would begin to act as the anode and corrode rapidly, leading to rust, pitting, and eventually, catastrophic structural failure.

The Heroic Sacrifice: Introducing Sacrificial Anodes

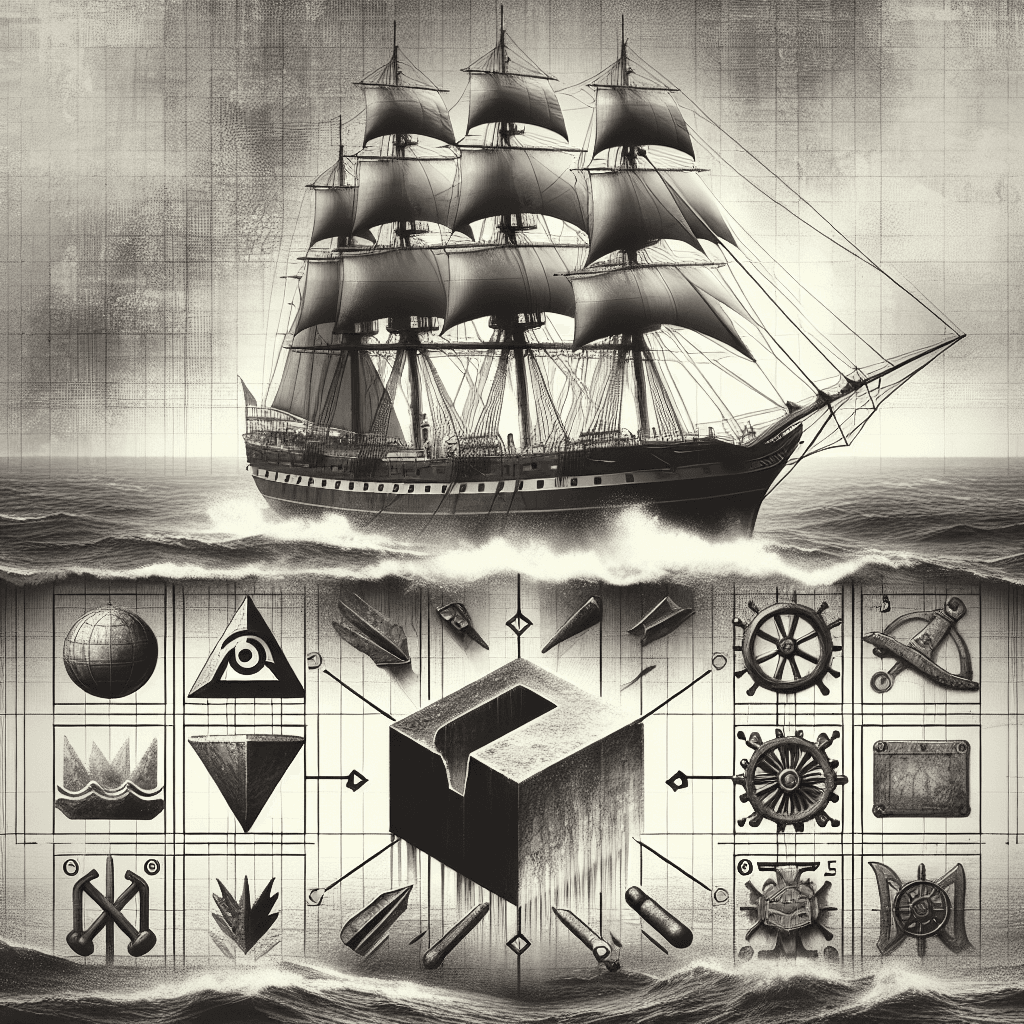

This is where our metal blocks come in. Known officially as sacrificial anodes, they are the designated heroes in this electrochemical battle. These blocks are made from a metal alloy that is more electrochemically active—or less "noble"—than the metals of the ship they are meant to protect.

The most common materials for sacrificial anodes in saltwater are:

- Zinc

- Aluminum

- Indium alloys

By attaching these anodes directly to the steel hull, engineers intentionally introduce a new, more appealing target for corrosion. The sacrificial anode becomes the most active metal in the circuit, turning into the anode. As a result, the ship's steel hull and expensive propeller become the cathode, and are protected from corrosion. The anode block corrodes, or "sacrifices" itself, slowly dissolving over time while the ship's vital structures remain intact. This entire system is a form of cathodic protection.

A Calculated Destruction

The use of sacrificial anodes is a precise science, not a haphazard guess. Marine engineers and naval architects carefully calculate the type, size, quantity, and placement of anodes needed to protect a vessel. They must consider several factors, including:

- The total surface area of the wetted hull and other underwater components.

- The type of metals being protected (e.g., steel, bronze).

- The type of water the ship will operate in (saltwater is far more corrosive than freshwater).

- The quality and type of anti-fouling paint on the hull, as this coating provides the first layer of defense.

These anodes are designed with a specific lifespan and are monitored as a key part of a ship's maintenance schedule. During a vessel's time in dry dock, one of the main tasks is to inspect and replace the worn-out anodes, ensuring the ship is ready for its next voyage with a fresh set of protectors.

Conclusion: A Small Price for a Mighty Ship

In the world of maritime engineering, sometimes the best defense is a calculated sacrifice. Those unassuming metal blocks are a simple, cost-effective, and brilliant solution to the complex problem of galvanic corrosion. By being deliberately designed to be destroyed, sacrificial anodes protect multi-million-dollar vessels, their cargo, and their crews from the relentless chemical forces of the sea. They prevent costly repairs, extend the operational life of a ship, and ensure its structural integrity. So, the next time you see a ship with these corroding blocks, you'll know they aren't a sign of neglect, but the mark of a well-protected vessel and its silent, metallic guardians.