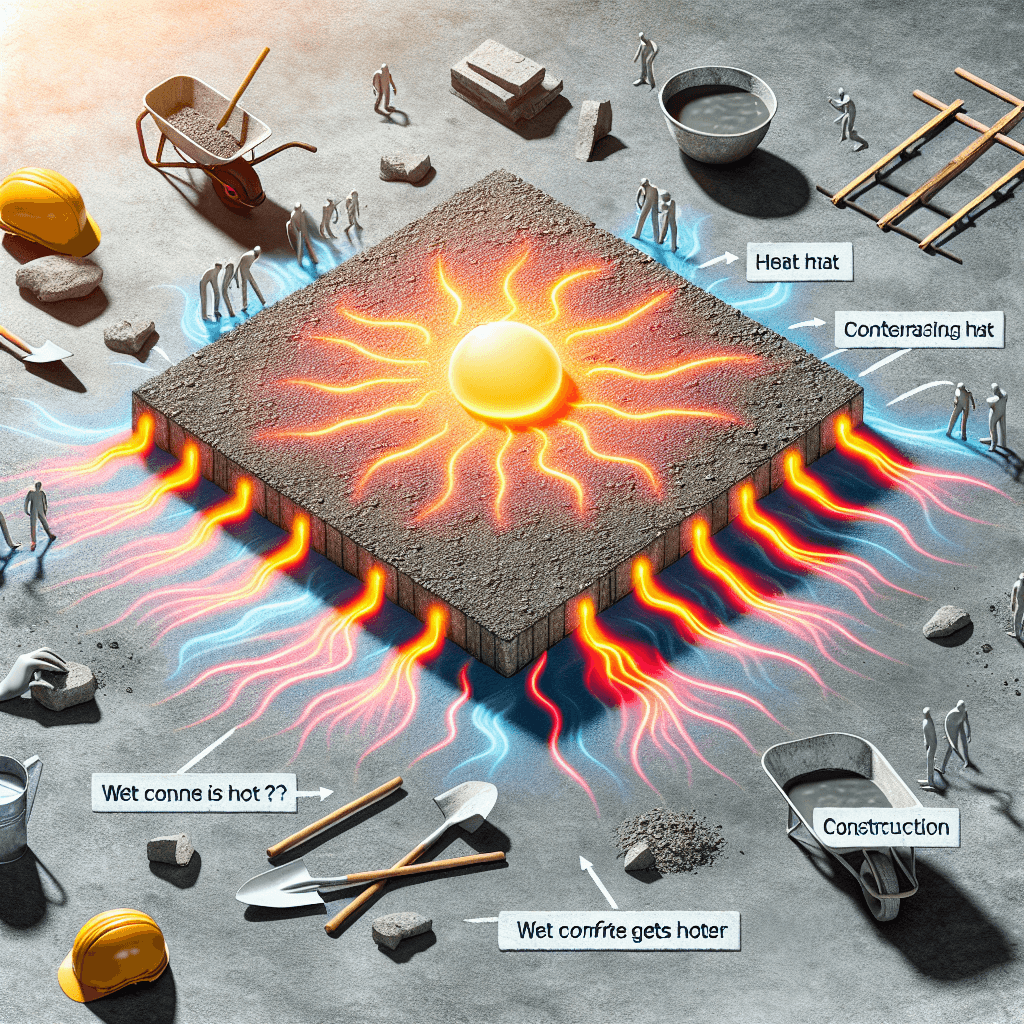

Feeling the Heat: Why Does Wet Concrete Actually Get Hot As It Hardens

Ever felt the surprising warmth radiating from a new sidewalk? It's not just the sun—it's a fascinating chemical reaction that generates its own heat as concrete hardens.

Too Long; Didn't Read

Wet concrete gets hot as it hardens because of a chemical reaction that releases energy as heat, not because it is simply drying out.

Feeling the Heat: Why Does Wet Concrete Actually Get Hot As It Hardens?

Ever walked past a construction site and noticed steam rising from freshly poured concrete, or perhaps even felt the surprising warmth radiating from a new sidewalk? It's not just the sun! Wet concrete genuinely generates its own heat as it transforms from a semi-liquid slurry into the rock-solid material we rely on for buildings, bridges, and roads. But why does this happen? It’s not simply drying out; a fascinating chemical process is at work. This post will delve into the science behind why wet concrete gets hot as it hardens, exploring the chemistry that builds our world.

What's Happening Inside the Mix?

To understand the heat, we first need to know what concrete is. It's essentially a composite material made up of three main components:

- Water: The catalyst for the reaction.

- Aggregate: Sand, gravel, or crushed stone that acts as filler and provides bulk.

- Cement: The crucial binding agent, typically Portland cement, that holds everything together.

While water and aggregate are relatively inert in this context, the magic – and the heat – comes from the reaction involving the cement.

The Chemistry of Hardening: Hydration

The process by which concrete hardens is not drying, although water does evaporate from the surface over time. The fundamental process is a chemical reaction called hydration. When water is added to cement, it triggers a complex series of chemical reactions between the water molecules and the compounds within the cement powder.

Key compounds in Portland cement, such as Tricalcium Silicate (C₃S) and Dicalcium Silicate (C₂S), react with water to form new, stable compounds. These new compounds are primarily calcium silicate hydrates (C-S-H gel) and calcium hydroxide (CH). The C-S-H gel is the "glue" that binds the aggregate particles together, forming a dense, interlocking crystalline structure. This structure is what gives concrete its strength and durability.

Introducing the Heat: An Exothermic Reaction

Now, here’s the crucial part: Hydration is an exothermic reaction.

- Exothermic Definition: In chemistry, an exothermic reaction is one that releases energy into its surroundings, typically in the form of heat.

Think of it like setting firewood ablaze; chemical bonds are broken and reformed, releasing energy as heat and light. Similarly, during cement hydration, the chemical bonds within the water and cement compounds are rearranged to form the new hydrate products. The formation of these new, more stable chemical bonds releases significantly more energy than was required to initiate the reaction. This excess energy is dissipated as heat, known as the heat of hydration.

Factors Influencing the Heat

The amount of heat generated isn't always the same. Several factors influence the temperature rise:

- Cement Type: Different types of cement have varying chemical compositions and fineness, affecting the rate and amount of heat released.

- Cement Content: More cement in the mix generally means more chemical reactions and thus more heat.

- Water-to-Cement Ratio: This ratio influences the reaction rate.

- Ambient Temperature: Concrete poured on a hot day will start warmer and may reach higher peak temperatures.

- Volume of Concrete: Larger concrete pours (like dams or thick foundations) retain heat more effectively because the surface area for heat dissipation is small relative to the volume generating heat. Temperatures inside massive concrete structures can rise significantly, sometimes exceeding 150°F (65°C) or more.

Managing the Heat in Construction

While the heat of hydration is a natural and necessary part of concrete gaining strength, excessive heat can be problematic, especially in large structures. Rapid or uneven temperature changes can cause thermal stress, potentially leading to cracking and compromising the concrete's long-term durability. Engineers and contractors often employ strategies to manage this heat, such as:

- Using cements designed to produce less heat.

- Cooling the mix ingredients (water or aggregate) before mixing.

- Placing concrete in smaller sections or layers.

- Embedding cooling pipes within large concrete pours to circulate cool water.

Conclusion: The Warmth of Strength

So, the next time you feel the warmth emanating from hardening concrete, you'll know it's not just drying in the sun. It's the tangible evidence of powerful chemical reactions taking place within the mix – the exothermic process of hydration. This heat release is a direct consequence of the formation of the strong, stable chemical bonds that transform a wet mixture into a durable construction material. Understanding this fundamental aspect of concrete behaviour is vital for ensuring the strength, safety, and longevity of the structures that shape our modern world. It’s chemistry you can feel!