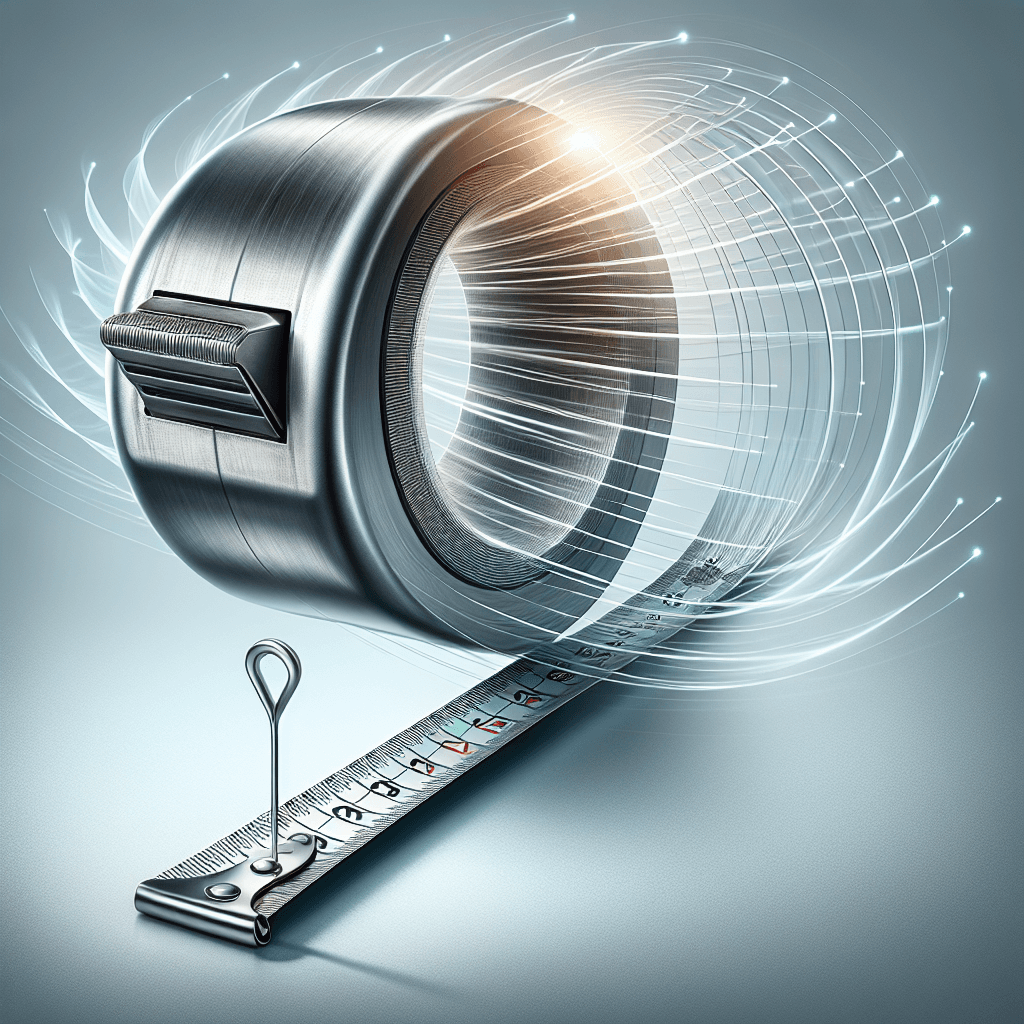

Why does the metal tip on a tape measure wiggle back and forth instead of being fixed

That annoying wiggle at the end of your tape measure isn’t a manufacturing defect—it’s actually a brilliant piece of engineering essential for pinpoint accuracy. Discover the secret reason why this "loose" part is the only thing standing between you and a DIY disaster.

Too Long; Didn't Read

The metal tip on a tape measure slides back and forth to account for the thickness of the hook itself. This movement ensures accuracy by adjusting the zero point depending on whether you are pulling against an edge for an outside measurement or pushing against a surface for an inside measurement.

Precision in Motion: Why Does the Metal Tip on a Tape Measure Wiggle Back and Forth Instead of Being Fixed?

Have you ever picked up a brand-new tape measure, noticed the metal tip sliding back and forth, and assumed the tool was poorly made or broken? It is a common frustration for DIY beginners and even some seasoned homeowners who might be tempted to "fix" the movement by tightening the rivets. However, that slight movement is actually one of the most critical design features of the tool. Far from being a manufacturing defect, the sliding metal tip—formally known as the "hook" or "tang"—is a precision-engineered necessity. This blog post explores the mechanical genius behind the "wiggle" and explains why this small amount of play is the secret to achieving a perfectly accurate measurement every single time.

Understanding the "True Zero" Concept

The primary reason the metal tip on a tape measure wiggles is to account for the thickness of the hook itself. In the world of carpentry and construction, this is known as achieving "True Zero." Whether you are measuring the outside of a piece of wood or the inside of a window frame, the starting point of your measurement (zero) must be exactly at the edge of the material.

If the hook were permanently fixed in one position, it would only be accurate for one type of measurement. By allowing the hook to slide, the tape measure automatically compensates for its own physical presence. According to tool design standards used by major manufacturers like Stanley and Lufkin, the distance of the "wiggle" is exactly equal to the thickness of the metal hook.

Measuring the Outside: The Pull Method

When you hook the end of the tape measure over the edge of a board to measure its length, you are performing an "outside measurement."

- The Action: As you pull the tape taut, the hook slides outward.

- The Result: The hook extends to its furthest point.

- The Accuracy: Because the hook has pulled away from the tape, the "zero" mark now starts exactly at the inside face of the hook, which is flush against the edge of your material.

In this scenario, the thickness of the metal tip is effectively moved outside of the measurement range, ensuring the tape begins counting from the very edge of the object.

Measuring the Inside: The Push Method

Conversely, when you need to measure the distance between two internal surfaces—such as the inside of a cabinet or a door frame—you use the "push method."

- The Action: You press the metal tip firmly against the surface.

- The Result: The hook slides inward toward the housing of the tape measure.

- The Accuracy: By sliding back, the hook compensates for its own thickness. The "zero" point of the measurement now shifts to the outside face of the hook.

Without this inward movement, your measurement would be off by about 1/16th of an inch (the typical thickness of the hook), leading to errors that could ruin a precision project.

Why You Should Never "Fix" the Rivets

A common mistake made by those unaware of this design is attempting to hammer the rivets flat to stop the tip from moving. Doing so effectively breaks the tool’s ability to calibrate itself.

- Fixed Hooks Lead to Constant Error: If you fix the hook in the "out" position, your inside measurements will always be too long.

- Calibration Issues: Professional-grade tape measures are calibrated so that the rivets themselves have enough clearance to allow for this precise travel.

- The Small Hole Mystery: You may also notice a small slot or hole in the hook. This is not for a screw; it is designed to hook onto a nail or screw head so you can measure solo, further highlighting the hook’s role as a versatile, moving anchor.

Conclusion

The sliding metal tip on a tape measure is a prime example of elegant mechanical engineering. While it may feel like a loose or low-quality component, the "wiggle" is a vital feature that allows the tool to maintain accuracy across both internal and external measurements. By moving a distance exactly equal to its own thickness, the hook ensures that "zero" is always exactly where it needs to be. Understanding this functional design not only helps you appreciate your tools more but also ensures you achieve the precision required for high-quality work. Next time you pull out your tape measure, remember that the wiggle isn't a flaw—it is the key to your project's success.