How did a massive, deadly wave of molasses once destroy a Boston neighborhood

It wasn't an ocean swell, but a 25-foot-tall wave of hot, sticky molasses that burst through a Boston neighborhood at 35 mph, crushing buildings and claiming 21 lives in one of history's strangest disasters.

Too Long; Didn't Read

TLDR: In 1919, a massive, poorly built tank of molasses burst on an unseasonably warm day in Boston. A 25-foot-high wave of syrup moving at 35 mph flooded a neighborhood, crushing buildings, killing 21 people, and injuring 150.

Sweet Terror: How Did a Massive, Deadly Wave of Molasses Once Destroy a Boston Neighborhood?

Imagine a tsunami, not of water, but of thick, brown, sticky syrup. It sounds like something from a bizarre fantasy, but on January 15, 1919, this surreal nightmare became a deadly reality for the residents of Boston’s North End. A 25-foot-high wave of molasses traveling at 35 miles per hour burst from a storage tank, obliterating everything in its path. This peculiar catastrophe, known as the Great Molasses Flood, claimed 21 lives, injured 150 more, and left an indelible scar on the city. This post delves into the shocking story of how a common sweetener caused one of history's strangest and most tragic industrial accidents.

The Ticking Time Bomb on the Waterfront

In the early 20th century, Boston’s North End was a bustling working-class neighborhood packed with homes and businesses. Dominating the landscape was a colossal steel tank owned by the Purity Distilling Company. Standing 50 feet tall and 90 feet in diameter, it was built to hold up to 2.3 million gallons of molasses.

At the time, molasses was a key ingredient in manufacturing industrial alcohol, which was used to make munitions for World War I. With demand high, the tank was often filled to capacity. However, it was a disaster waiting to happen.

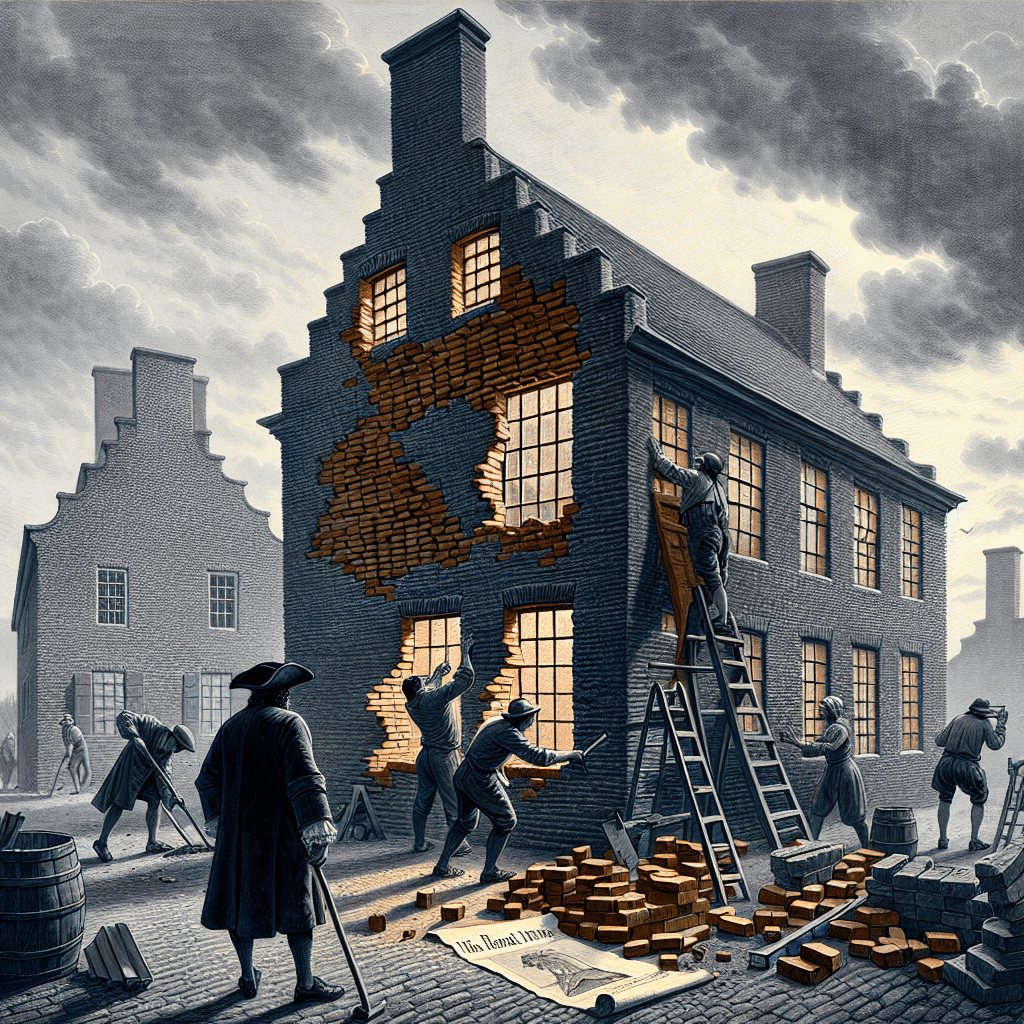

- Shoddy Construction: The tank was built in a hurry, with steel plates that were too thin and brittle for the immense pressure they had to contain. Safety testing was virtually nonexistent.

- Ominous Warning Signs: Local residents reported that the tank groaned and shuddered when it was full. It leaked so badly that children would collect the sweet drippings in pails. To hide the problem, the company simply painted the tank brown, the same color as the leaking molasses.

A Wall of Syrup Unleashes Hell

The day of the disaster, January 15, 1919, was unseasonably warm. Temperatures rose from near-freezing to over 40°F (4°C), causing the molasses inside the overfilled tank to expand. Just after 12:30 PM, the strain became too much.

Witnesses heard a sound like a machine gun as rivets shot out of the tank's seams, followed by a thunderous roar. The tank’s walls ripped apart, unleashing a torrent of molasses. This wasn't a slow ooze; it was a violent, destructive wave. The sheer density of the molasses—about 40% heavier than water—gave the wave immense force. It flattened buildings, buckled the steel girders of the elevated railway, and swept people, horses, and wagons into its suffocating grip. The immense pressure wave it created was powerful enough to knock people off their feet blocks away.

The Aftermath: A Deadly, Sticky Mess

The scene was one of utter devastation. First responders and volunteers waded into the waist-deep, viscous mess, struggling to pull victims from the hardening goo. The molasses clogged the streets, making rescue efforts agonizingly slow. As temperatures dropped that evening, the syrup thickened, trapping victims and making the cleanup even more difficult. It took more than 80,000 man-hours to chip and wash away the sticky residue from the cobblestone streets. For months, Boston Harbor was stained brown as crews used saltwater hoses to clean the area.

The Cause and the Consequences

While Purity Distilling’s parent company, United States Industrial Alcohol, initially tried to blame the disaster on an anarchist bomb, the truth emerged in one of the first class-action lawsuits in Massachusetts history. After years of testimony, investigators concluded the flood was caused by a fatal combination of factors:

- Structural Failure: The tank was poorly designed and built with inadequate materials.

- Thermal Stress: The rapid temperature change caused the molasses to expand, placing unbearable stress on the already-faulty tank.

- Lack of Regulation: At the time, there were few regulations governing the construction of such large industrial projects.

The court found the company entirely responsible. The Great Molasses Flood became a landmark case, setting a legal precedent for corporate accountability and leading to the adoption of stricter engineering and construction standards across the United States, including requirements for certified engineers to sign off on building plans.

Conclusion

The Great Molasses Flood stands as a bizarre but potent reminder of the catastrophic consequences of corporate negligence and cutting corners on safety. What began as a sweet commodity ended as an agent of destruction, forever changing a Boston neighborhood and influencing industrial regulation for a century to come. Even today, some longtime residents claim that on hot summer days, a faint, sweet smell of molasses still hangs in the air of the North End—a ghostly echo of that tragic winter afternoon when a city was brought to its knees by a wave of syrup.