What makes a vending machine spit out a perfectly good dollar bill

It’s not the wrinkles; vending machines are high-tech counterfeit detectives scanning for hidden signals in the ink and paper. We’ll reveal the surprising reasons your perfectly good bill keeps failing its secret test.

Too Long; Didn't Read

TLDR: Vending machines reject bills that are too wrinkled, torn, faded, or dirty because their sensitive scanners cannot properly read the security features. The machine's internal sensors could also be dirty or worn out, causing them to misread even a perfect bill.

Decoding the Rejection: What Makes a Vending Machine Spit Out a Perfectly Good Dollar Bill?

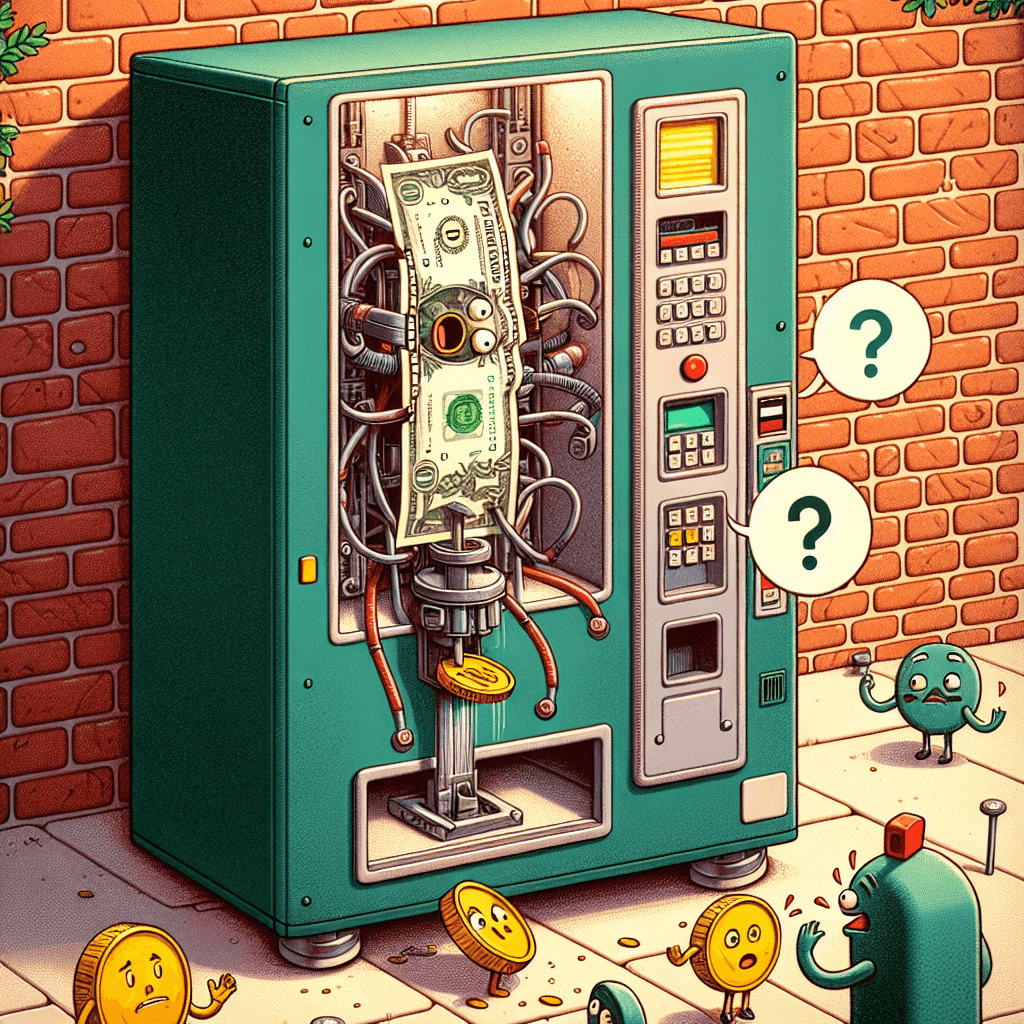

We’ve all been there: standing in front of a vending machine, stomach rumbling, only to have your perfectly good, legal-tender dollar bill rejected again and again. You smooth it out, flip it over, and try one more time, but the machine stubbornly spits it back out. It’s a moment of modern-day frustration that feels almost personal. Is the machine just being picky? The truth is far more technical. That simple slot on the vending machine conceals a sophisticated piece of technology designed for one primary purpose: security. This post will demystify the process, exploring the inner workings of a bill validator and the precise reasons why your seemingly fine dollar fails its high-tech inspection.

The Inner Workings: A Glimpse Inside the Bill Validator

When you insert a dollar bill into a vending machine, you’re not just sliding it into a simple box. You are feeding it into a complex scanner known as a bill validator or bill acceptor. This device acts as a high-tech security checkpoint for your cash, running it through a series of tests in a fraction of a second. If the bill fails any single test, it’s immediately rejected.

The validator pulls the bill along a mechanical path lined with various sensors, each looking for specific characteristics. These typically include:

- Optical Sensors: A set of light sensors (often using visible and infrared light) scans the bill to create a digital image. This image is compared against a database of known genuine currency. The sensors check for the correct size, centering of the portrait, and the specific patterns and colors of the ink.

- Magnetic Sensors: The black ink used for the portraits and seals on U.S. currency contains trace amounts of iron oxide, making it magnetic. Magnetic sensors scan the bill to detect the presence and specific signature of this ink, a key feature in deterring counterfeiting.

- Dielectric Sensors: These sensors measure the unique electrical properties of the paper itself. The specific blend of cotton and linen used for U.S. currency has a distinct dielectric profile that is difficult for counterfeiters to replicate with standard wood-pulp paper.

Common Culprits: Why Your "Good" Dollar Gets Rejected

A dollar that looks perfectly usable to the human eye can fail the machine’s rigorous tests for several reasons. The sensors are precise, and even minor imperfections can result in a rejection.

1. Folds, Creases, and Wrinkles

This is the most common reason for rejection. A bill needs to be relatively flat to pass cleanly over the sensors. A sharp crease or a deep wrinkle can distort the bill's image just enough that the optical scanner can't match it to its internal reference file. The machine interprets this distortion as a potential counterfeit or a foreign object. Smoothing the bill out on a flat surface often resolves this issue.

2. Dirt, Stains, and Fading

A bill that has been through the wash or has a significant stain on it can fail the optical test. The discoloration can block the sensors from reading the intricate details of the bill's design. Similarly, an older, heavily circulated bill may have faded ink. If the ink is too faint, the magnetic sensors may not pick up a strong enough signal, leading to an automatic rejection.

3. Tears, Holes, and Tape

Even a minuscule tear along the edge or a tiny pinhole can interrupt the optical scan. These imperfections alter the bill's expected dimensions and appearance. Any tape on a bill is an immediate red flag for the validator's sensors, as it changes the thickness, texture, and optical properties of the paper, causing the machine to reject it instantly.

4. Excessive Wear and "Limpness"

Over time, the cotton and linen fibers in a dollar bill break down, making it soft and limp. While still legal tender, these overly "soft" bills can have trouble navigating the mechanical path inside the validator. More importantly, their dielectric properties can change slightly with wear and humidity, causing them to fail the paper-type test. A crisp, newer bill almost always has a higher success rate.

5. Machine Calibration and Cleanliness

Sometimes, the problem isn't the bill—it's the machine. The optical sensors inside a bill validator can become coated with dust, dirt, and residue from the thousands of bills they process. This grime can obstruct the sensor's view, leading to false rejections. Additionally, if the machine’s software or calibration is outdated, it may not recognize newer bill designs or have overly strict validation criteria.

Conclusion

The next time a vending machine rejects your dollar, remember it’s not a personal slight. It’s a sign of a sophisticated security system doing its job. The validator’s goal is to protect the machine's owner from fraud by meticulously checking every bill against a strict set of criteria, from its magnetic ink to the specific properties of its paper. This technology, while occasionally frustrating for the consumer, is a crucial defense against counterfeit currency. So, instead of getting angry at the machine, try a different, crisper bill. In the world of automated transactions, a clean, flat dollar is always your best bet for success.