Why are cracks in pavement often filled with a black, tar-like substance

Those black, tar-like lines aren't just an ugly patch—they're the critical 'stitches' that stop a tiny crack from destroying the entire road.

Too Long; Didn't Read

The black substance is a flexible, waterproof sealant used to fill cracks in pavement. This keeps water from getting underneath, freezing, and expanding, which prevents small cracks from turning into large potholes and extends the road's lifespan.

Road Remedies: Why Are Cracks in Pavement Often Filled with a Black, Tar-Like Substance?

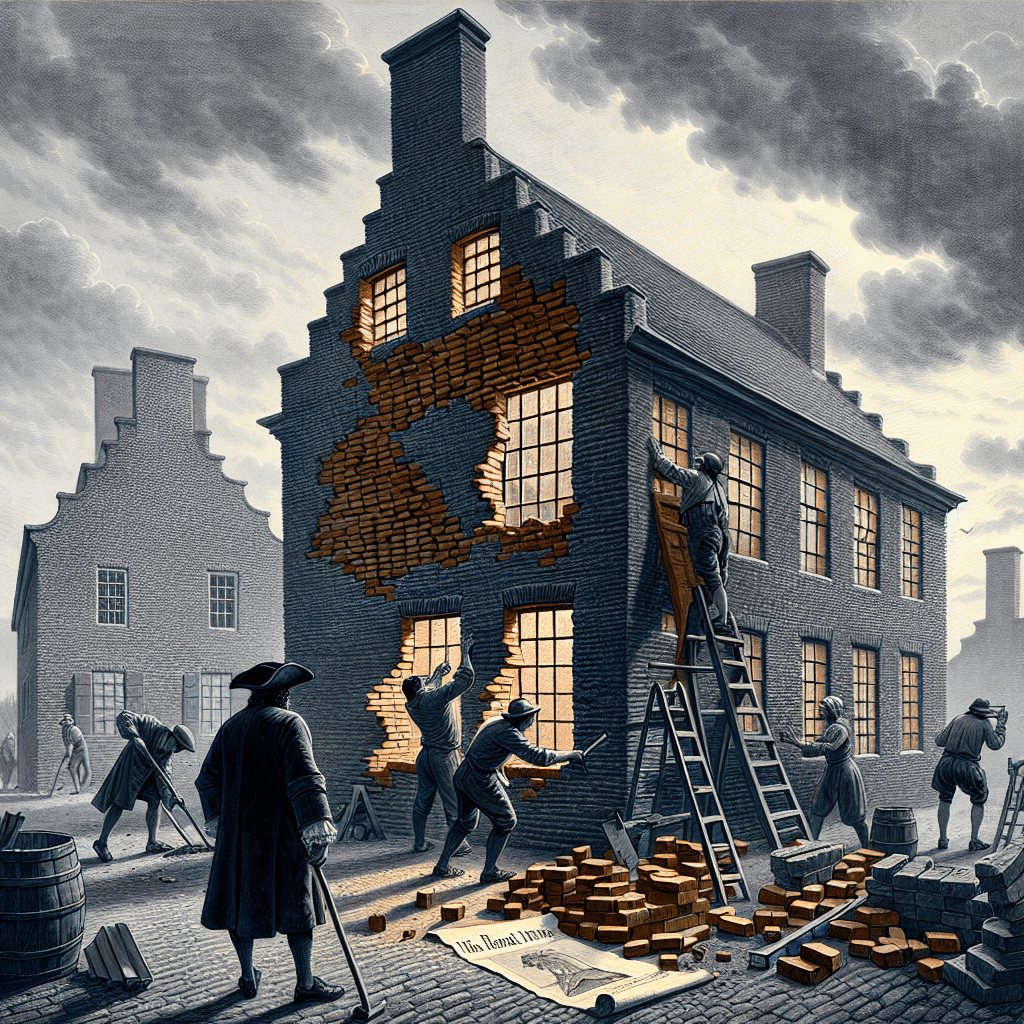

Have you ever been driving or walking through a parking lot and noticed the dark, serpentine lines that seem to stitch the pavement together? These black patterns are a common sight on roads, highways, and runways across the world. While they might look like simple, messy repairs, they are actually a crucial and highly engineered part of infrastructure maintenance. These black lines are not just covering up imperfections; they are actively protecting the pavement from its greatest enemy. This post will delve into the science behind this common practice, explaining exactly what that black, tar-like substance is and why it's so vital for preserving our roads.

## What is That Black, Tar-Like Substance?

First, let's clear up a common misconception. While it's often called "tar," the substance used to fill cracks in modern pavement is typically a more advanced material known as a hot-pour rubberized asphalt sealant.

This is not the same as the asphalt concrete used to build the road itself. Instead, it’s a specialized blend designed for a specific purpose. The primary ingredient is asphalt binder, a sticky, black, petroleum-based substance. However, it's modified with polymers—essentially, synthetic rubber—and other additives. This combination creates a material that is far superior to simple tar or standard asphalt for sealing cracks. It's heated to a high temperature (often over 350°F or 177°C) to become a liquid, allowing it to be poured deep into the cracks before it cools and solidifies.

## The Primary Goal: Keeping Water Out

The single most important reason for sealing cracks in pavement is to prevent water infiltration. Water is the number one cause of pavement deterioration. When left unsealed, even a small crack becomes a direct channel for water to seep below the surface and into the road's foundation, or subgrade. This leads to two major problems.

The most destructive is the freeze-thaw cycle.

- Water enters a crack in the pavement.

- When temperatures drop below freezing, that water turns to ice and expands by about 9%.

- This expansion exerts immense pressure on the surrounding pavement, widening and deepening the crack.

- When the ice thaws, more water can now enter the larger crack, and the destructive cycle repeats.

This process quickly breaks down the pavement, turning small cracks into large, dangerous potholes. Even in climates without freezing temperatures, water can erode the granular base layers beneath the asphalt, weakening the road's structural integrity and leading to sagging, rutting, and eventual failure.

## The Science of Sealing: Why It Works

The engineered properties of hot-pour sealant make it the perfect defender against water damage. Its effectiveness comes down to a few key characteristics:

- Flexibility: Pavement naturally expands in the heat and contracts in the cold. The polymers in the sealant give it a rubber-like elasticity, allowing it to stretch and compress along with the pavement without breaking the seal.

- Adhesion: The sealant is designed to bond tenaciously to the sides of the crack. This strong bond ensures that no gaps form, creating a truly watertight barrier.

- Waterproofing: The asphalt base of the sealant is naturally waterproof, forming an impermeable layer that blocks moisture from rain, snow, and ice.

- Durability: It is engineered to withstand the daily stresses of traffic, UV radiation from the sun, and exposure to vehicle oils and fuels.

## A Stitch in Time: The Economics of Road Maintenance

Beyond the technical benefits, sealing cracks is a cornerstone of preventative maintenance and is incredibly cost-effective. Treating a small crack is a relatively quick and inexpensive process. However, ignoring that crack until it becomes a pothole or causes larger structural damage requires far more extensive, expensive, and traffic-disrupting repairs.

According to research supported by the U.S. Federal Highway Administration, every dollar spent on pavement preservation, such as crack sealing, can save between six and ten dollars in future rehabilitation costs. By investing in this proactive strategy, transportation agencies can significantly extend the lifespan of a road, ensuring safer travel and saving taxpayer money in the long run.

## Conclusion

So, those black lines crisscrossing our roads are much more than a cosmetic fix. They are a sophisticated defense system—a flexible, durable, and waterproof sealant designed to combat pavement's greatest foe: water. By stopping the destructive freeze-thaw cycle and preventing foundational erosion, this simple-looking black substance plays a massive role in maintaining the safety and longevity of our vital transportation infrastructure. The next time you see a road crew applying these dark, molten lines, you’ll know they aren’t just patching a problem; they’re implementing a smart, cost-effective strategy to protect the very foundation beneath your wheels.