Why can you tear paper easily in one direction but not the other

That satisfyingly straight tear versus a frustrating, ragged mess is no accident; it’s a story told by invisible highways of fibers locked within every single sheet.

Too Long; Didn't Read

TLDR: Paper is made of tiny fibers that align in one direction during manufacturing, creating a grain. Tearing with the grain is easy because it just separates the fibers, while tearing against the grain is hard because you have to break them.

The Grain of Truth: Why Can You Tear Paper Easily in One Direction But Not the Other?

Have you ever tried to tear a neat strip from a sheet of paper, only to have it veer off course, leaving a jagged, messy edge? Yet, when you try again from a different side, it rips in a perfectly straight line. This isn't a random quirk or a test of your dexterity; it's a fundamental property of paper itself. This common experience reveals a hidden structure within every sheet, an invisible guide that dictates its strength and weakness. Understanding this phenomenon not only solves a minor daily frustration but also unveils the fascinating science behind how paper is made and used in everything from books to packaging. This post will explore the concept of "paper grain" and explain exactly why this directional difference exists.

The Secret is in the Fibers: Understanding Paper Grain

At its most basic level, paper is a matted web of tiny cellulose fibers, typically derived from wood pulp. These fibers are the building blocks, but they aren't arranged randomly like a pile of hay. Instead, they have a tendency to align themselves in a specific direction. This dominant alignment is known as the paper grain, or the machine direction.

Think of it like the grain in a piece of wood. It's much easier to split a log along its grain than to chop through it. Similarly, paper has a "grain direction" and a "cross direction."

- Grain Direction: The direction in which the majority of the fibers are aligned. Tearing along this path is easy and results in a relatively straight line.

- Cross Direction: The direction perpendicular to the grain. Tearing this way is difficult and produces a jagged, irregular edge.

This directional property, known as anisotropy, is the root cause of our paper-tearing puzzle. The strength of the paper isn't uniform; it is significantly stronger across the grain than it is with it.

From Pulp to Paper: How the Grain is Made

The creation of paper grain is a direct result of the manufacturing process. Most modern paper is made on a large piece of equipment called a Fourdrinier machine. The process, in a simplified sense, creates the grain in a crucial step:

- Creating the Slurry: Wood is broken down into a watery pulp, creating a slurry that is about 99.5% water and 0.5% cellulose fiber.

- Formation on the Wire: This slurry is sprayed onto a large, fast-moving mesh screen, often called the "wire."

- Alignment: As the slurry travels forward on this moving screen, the water begins to drain away. The forward momentum of the screen encourages the long, thin cellulose fibers to align themselves parallel to the direction of travel, much like logs floating down a river.

This forward movement locks the majority of fibers into a uniform direction. As the sheet continues through rollers that press out more water and then through a heated drying section, this alignment becomes a permanent feature of the finished paper. The direction the paper was traveling on the machine becomes the "grain direction."

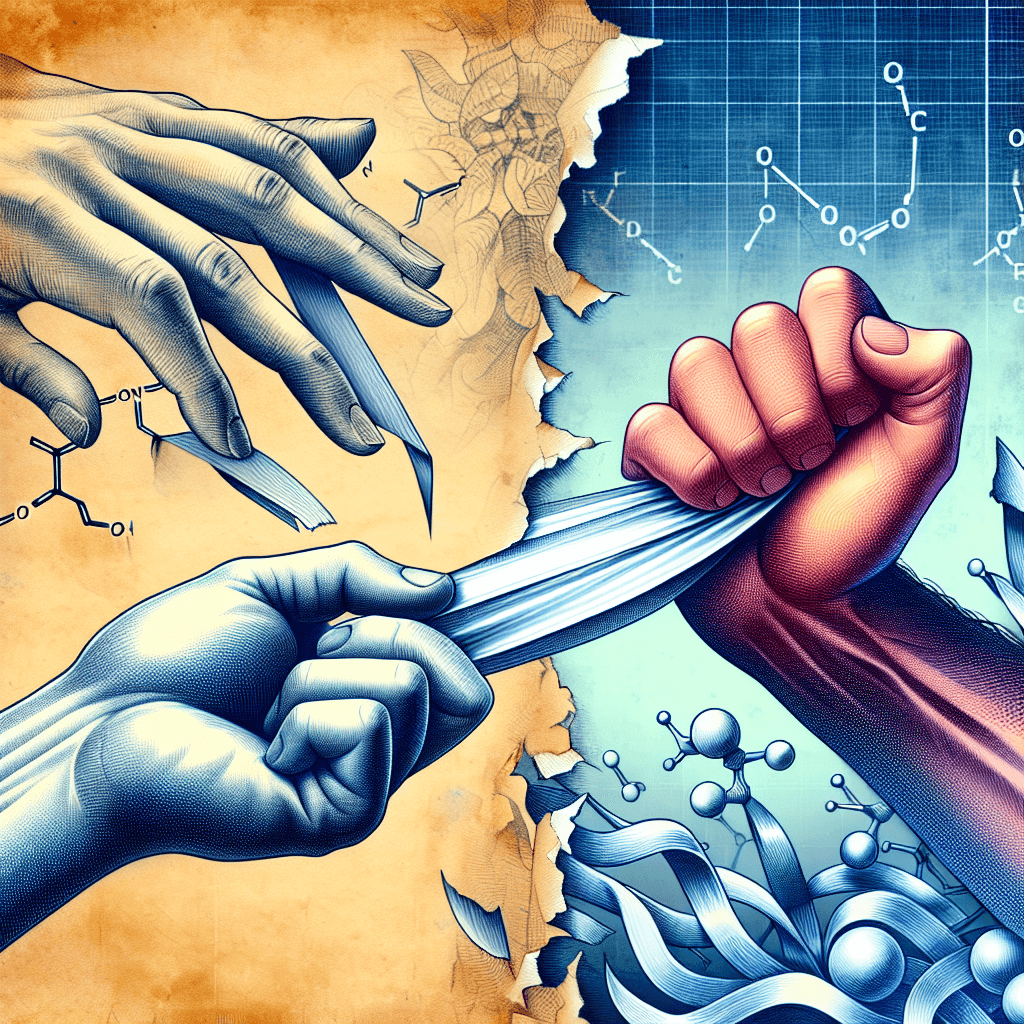

Tearing With and Against the Grain

Now, the tearing experience makes perfect sense.

When you tear with the grain (parallel to the fibers), you are essentially just separating the fibers from each other along their length. The tear follows the natural, weak path between the fibers, requiring little force and creating a clean rip.

Conversely, when you tear against the grain (perpendicular to the fibers), you are not separating them but are forced to snap each individual fiber in your path. This requires significantly more energy and results in a ragged tear because the rip struggles to break through the stronger, interlocking web of fibers.

Why Does Paper Grain Matter?

This property is far from a simple curiosity; it is a critical consideration in the printing and bookbinding industries.

- Bookbinding: For a book to open properly and for its pages to lie flat, the grain must run parallel to the spine. If it runs perpendicular (cross-grain), the pages will be stiff, resist turning, and won't lie flat.

- Folding: When creating brochures, cards, or packaging, folding with the grain produces a sharp, clean crease. Folding against the grain can cause the paper fibers to crack and break, resulting in a rough and unprofessional-looking fold.

- Printing: Paper can stretch slightly more against the grain when it absorbs moisture from ink. For precise color registration in commercial printing, knowing the grain direction is essential to prevent misaligned images.

Conclusion

The simple act of tearing a piece of paper reveals a fascinating story about its creation. The difference between a clean tear and a jagged mess is not luck but a direct consequence of the manufacturing process, where cellulose fibers align to form the paper's "grain." This inherent directionality is a crucial property that affects how paper behaves, influencing everything from how we read a book to how we fold a birthday card. So, the next time you tear a sheet of paper, you can appreciate the hidden structure at play. You aren't just tearing paper; you're interacting with the very flow of its creation.