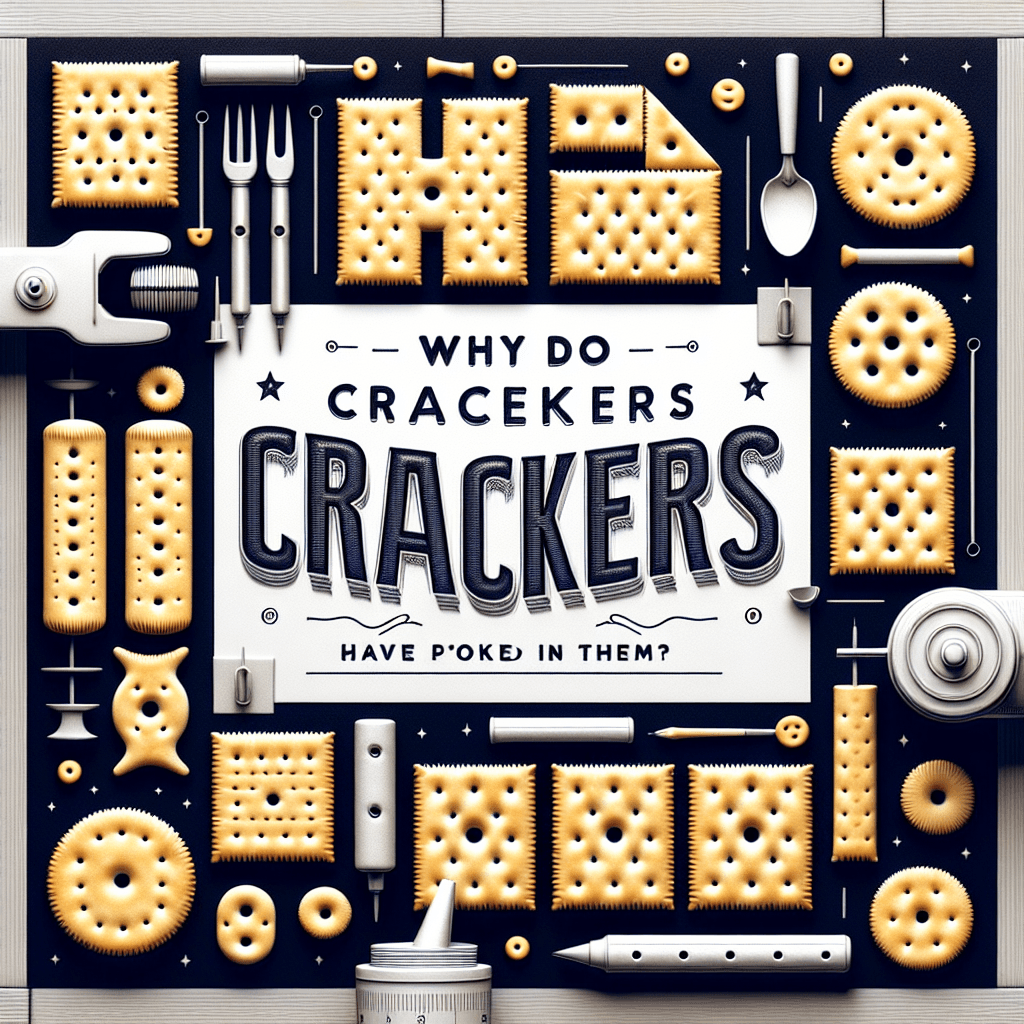

Why do crackers have little holes poked in them

Those little holes aren't just for decoration; they're the only thing stopping your crispy snack from becoming a puffy, chewy disaster in the oven.

Too Long; Didn't Read

TLDR: The holes let steam escape during baking, which keeps the crackers flat and crispy instead of puffing up into puffy, uneven air bubbles.

The Hole Story: Why Do Crackers Have Little Holes Poked in Them?

Have you ever found yourself gazing into a box of crackers, perhaps just before building the perfect cheese and cracker stack, and wondered about the tiny, uniform holes dotting their surface? Are they a secret code? A quirky design choice? The truth is far more scientific and crucial to the cracker's very existence than you might think. These small perforations are not for decoration; they are the result of a deliberate and essential step in the baking process.

This blog post will unravel the snack-time mystery behind those little holes. We will delve into the food science that makes a cracker crispy instead of puffy, exploring the specific role these perforations play in engineering the perfect, crunchy bite. Prepare to see your favorite snack in a whole new, well-ventilated light.

The Science of Steam: Preventing the Puff

The main reason for the holes in crackers can be summed up in one word: steam. Like any bread-based product, cracker dough contains water. When the thin sheets of dough enter a hot oven, this water quickly heats up and turns into steam.

Without an escape route, this expanding steam would get trapped, forming large, random air pockets. This would cause the cracker to puff up unevenly, much like a pita bread or a dinner roll. The final product would be soft, puffy, and anything but the flat, crispy snack we know and love. The holes act as tiny chimneys, providing a planned escape route for the steam to vent out of the dough as it bakes. This ensures the cracker remains flat and cooks evenly.

Engineering the Perfect Crunch: Enter the Docker

The process of poking these holes into the dough is known in the baking world as "docking." Before the large sheets of cracker dough are baked, they are passed under a machine called a docker. This machine is typically a large roller covered in a precise pattern of small spikes. As the dough sheet passes underneath, the docker perforates it with the familiar pattern of holes.

The placement and number of these holes are no accident. Food scientists and bakers carefully calculate the pattern to ensure optimal steam release.

- Too few holes, and the cracker will still puff up in the areas between them.

- Too many holes, and the cracker could become overly dry, dense, or brittle.

The goal is to achieve the perfect balance that allows the cracker to bake into a thin, crisp, and structurally sound wafer.

The Benefits of a Well-Docked Cracker

The primary function of docking is to control steam, but this single process leads to several key characteristics that define a great cracker:

- Consistent Flatness: By preventing large air bubbles, docking ensures that crackers bake to a uniform flatness. This is essential not only for the eating experience but also for packaging, as flat crackers can be stacked neatly without breaking.

- Signature Crispy Texture: The controlled release of steam is what allows the cracker to dry out properly in the oven, achieving that satisfying, brittle snap. Without docking holes, the trapped moisture would result in a soft, chewy texture.

- Even Baking: The holes also help heat penetrate the dough more evenly. This prevents the dreaded scenario of burnt edges and an undercooked center, ensuring a perfectly golden-brown cracker from edge to edge.

While the primary function of docking holes is scientific, the specific pattern can also become a part of a brand's identity. The tightly spaced grid on a saltine is different from the pattern on a Ritz for a reason—it's all part of a carefully engineered recipe for a unique texture and appearance.

Conclusion

Those seemingly insignificant holes in your crackers are, in fact, a brilliant example of food engineering at work. They are not a decorative flourish but a critical feature designed to vent steam, control the baking process, and ultimately create the perfectly flat and crispy snack. The process, known as docking, is the unsung hero responsible for preventing a potential puffy disaster in the oven.

So, the next time you pick up a cracker, take a moment to appreciate the science behind its humble design. Each tiny hole is a testament to the precision required to deliver that satisfying crunch, proving that sometimes, the most important elements are the ones we take for granted.