Why do so many pill capsules have two different colored halves

It's not a style choice—that two-toned pill capsule is actually a brilliant engineering hack that solves a massive, high-speed problem on the factory floor.

Too Long; Didn't Read

TLDR: The two colors streamline manufacturing, helping machines quickly orient the cap and body for assembly. The color combinations also act as branding and help everyone from pharmacists to patients easily identify specific drugs and dosages, reducing errors.

More Than Just Design: The Real Reason Why So Many Pill Capsules Have Two Different Colored Halves?

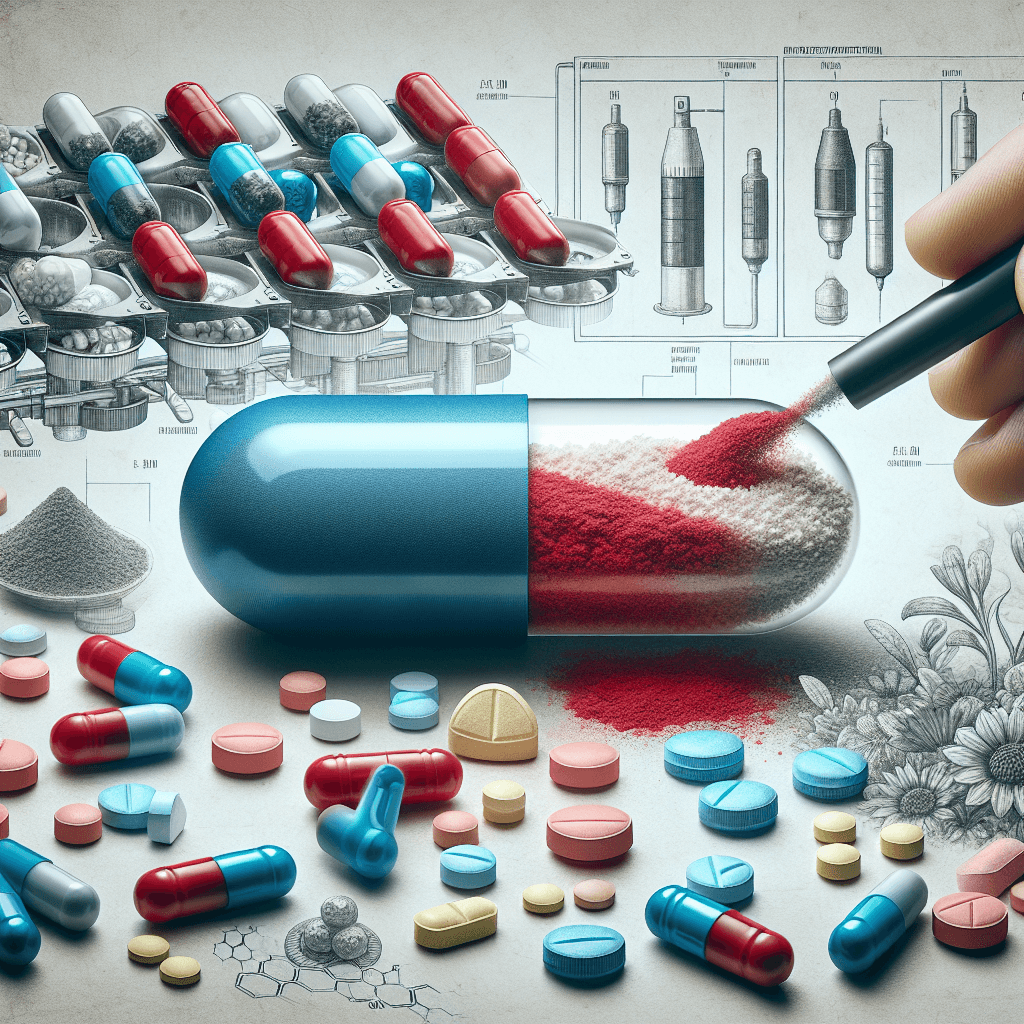

Take a look inside your medicine cabinet. If you have any medications that come in capsule form, you'll likely notice a common design trait: many of them are two-toned, with a differently colored cap and body. You might have assumed this was a purely aesthetic choice, a simple way to make medicine look more appealing. While branding plays a part, the primary reasons for this design are far more practical, rooted in manufacturing efficiency, quality control, and patient safety. This seemingly minor detail is actually a brilliant piece of industrial design that streamlines production and helps prevent critical errors. This post will uncover the precise reasons why that little pill in your hand has two distinct colors.

The Manufacturing Advantage: Speed and Accuracy

The most significant reason for two-toned capsules lies in the mechanics of high-speed manufacturing. A standard gelatin capsule consists of two parts:

- The Body: The longer, narrower half that is filled with the active pharmaceutical ingredient (API) and other inactive ingredients.

- The Cap: The shorter, wider half that slides over the body to seal the capsule.

Pharmaceutical factories use incredibly fast automated machines that can fill and seal tens of thousands of capsules per hour. For this process to work flawlessly, the machine must orient each empty capsule correctly before filling it. It needs to know which end is the body (to be filled) and which is the cap (to be placed on top).

This is where the two colors come in. Optical sensors on the assembly line can instantly detect the color difference, allowing the machine to sort and align the halves with near-perfect accuracy and at incredible speeds. A single-color capsule would be much harder for machinery to orient, leading to a higher rate of errors, such as:

- Capsules being joined empty.

- Two bodies or two caps being incorrectly matched.

- The machine jamming, causing costly production delays.

By using a differently colored (and often fractionally wider) cap, manufacturers ensure the production line runs smoothly, efficiently, and with minimal error.

A Crucial Tool for Safety and Identification

Beyond the factory floor, the two-color design serves as a vital safety feature for healthcare professionals and patients alike. In a busy pharmacy or hospital, where hundreds of different medications are handled daily, distinct visual cues are essential for preventing mix-ups.

For Pharmacists and Healthcare Providers

A unique color combination acts as a quick visual identifier for a specific drug and dosage. It helps a pharmacist double-check that they are dispensing the correct medication, reducing the risk of human error. The U.S. Food and Drug Administration (FDA) even encourages unique physical attributes for drugs to minimize confusion. This visual distinction is one of the first lines of defense against potentially dangerous medication errors.

For Patients

For individuals managing multiple health conditions, keeping track of different pills can be overwhelming. A capsule with a distinct blue and white body is much easier to distinguish from an all-red one. This color-coding helps patients, particularly the elderly, adhere to their medication schedules correctly. It empowers them to identify their pills confidently, reducing the risk of accidentally taking the wrong drug or the wrong dose.

Branding and Anti-Counterfeiting

Finally, while function is the primary driver, form and branding are also important. Pharmaceutical companies invest heavily in developing their products, and a distinctive look helps build brand recognition.

Just as you can recognize a brand by its logo, a specific color combination can make a medication instantly identifiable. This helps differentiate a brand-name drug from its generic counterparts and builds consumer trust.

Furthermore, this unique appearance serves as a tool against counterfeit drugs. If a patient receives a medication that looks different from what they normally take—for instance, a solid green capsule instead of the familiar green and white one—it serves as an immediate red flag. This encourages them to verify the medication with their pharmacist, protecting them from potentially ineffective or harmful fake products.

Conclusion

So, the next time you see a two-colored pill capsule, you’ll know it’s much more than a style choice. That simple design is a testament to thoughtful engineering that bridges manufacturing precision with everyday patient safety. From ensuring automated machines work flawlessly to helping a pharmacist quickly identify a drug and empowering a patient to manage their health confidently, the two-toned capsule is a small but powerful example of how smart design plays a critical role in modern medicine. It's a clever, multi-faceted solution that keeps the pharmaceutical industry running efficiently and, most importantly, helps keep us safe.