Why do the metal prongs on some electrical plugs have tiny holes in them

It's not a manufacturing defect or a random design choice; those tiny holes are actually a clever safety feature that grips the inside of your outlet.

Too Long; Didn't Read

TLDR: The holes on plug prongs are for grip. They lock onto small bumps inside an electrical outlet, creating a secure connection so the plug doesn’t easily fall out.

Holey Plugs, Explained: Why Do the Metal Prongs on Some Electrical Plugs Have Tiny Holes in Them?

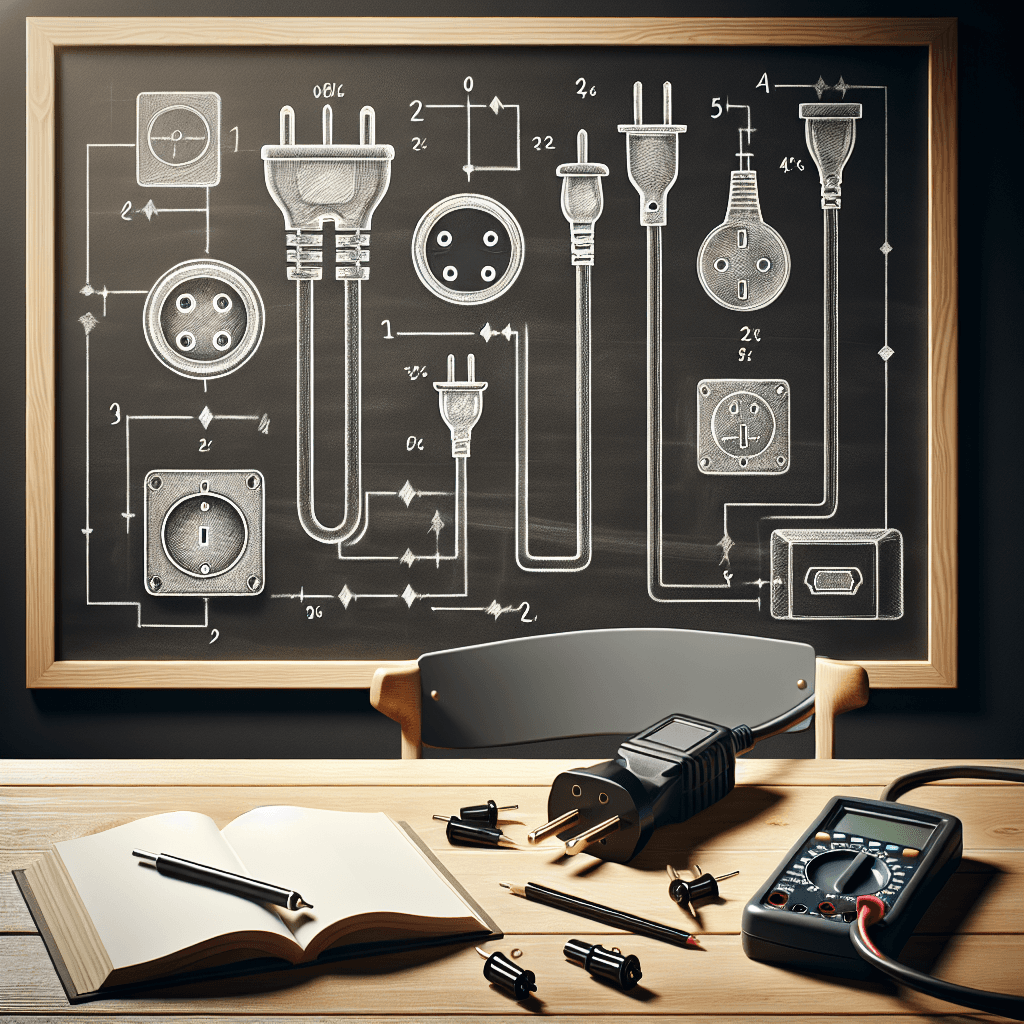

Have you ever unplugged your phone charger or a lamp and paused for a moment, noticing the two small holes near the tips of the metal prongs? It’s a feature so common on North American plugs that we often overlook it. But these holes are not a random design quirk or a manufacturing defect. They are a clever and intentional piece of engineering that serves a few important functions, primarily centered around safety and a secure connection.

This seemingly minor detail is a perfect example of the hidden ingenuity in everyday objects. In this post, we will demystify the purpose of these holes, exploring the primary reason they exist, their role in the manufacturing process, and debunking a few popular myths along the way. Prepare to have your curiosity satisfied and to never look at an electrical plug the same way again.

The Primary Reason: A Firm Grip

The most crucial reason for the holes in plug prongs is to ensure the plug stays firmly seated in an electrical outlet. If you were to look inside a modern wall socket, you would find small bumps or sprung "wipers" on the metal contact clips that receive the prongs.

Here’s how it works:

- Insertion: As you push the plug into the outlet, the prongs slide past these internal bumps.

- Locking In: Once the prongs are fully inserted, the bumps on the outlet’s contacts align with the holes on the prongs and "fall" into place.

- Tension: This creates a slight tension, effectively gripping the prongs and holding the plug securely in the socket.

This simple mechanism prevents the plug from easily slipping out due to the weight of the cord or an accidental, gentle tug. It ensures a consistent and safe flow of electricity by maintaining a solid connection, reducing the risk of arcing—a dangerous electrical spark that can occur when a plug is loose.

A Helping Hand in Manufacturing

Beyond keeping the plug in the wall, these holes also play a role before the plug ever leaves the factory. During the assembly process, manufacturers need a way to hold the metal prongs perfectly still while the plastic or rubber housing is molded around them.

The holes provide a convenient anchor point. Machines can insert pins through the holes to secure the prongs in the mold, ensuring they are perfectly aligned and embedded within the plug body. This leads to a more consistently built, durable, and safer product. While not the primary purpose for the end-user, it's a significant manufacturing benefit that streamlines production.

Debunking Common Myths

Over the years, several popular but incorrect theories about the holes have emerged. Let’s clear a few of them up.

- Myth: They are for padlocks. While you might be able to fit a tiny lock through the holes, this is not their intended purpose for consumer use. In industrial settings, this feature can be used for "lockout/tagout" procedures, where a tag or lock is applied to prevent machinery from being turned on during maintenance. For home use, however, this is not a practical security feature.

- Myth: They save on material. The amount of metal saved by punching these tiny holes is minuscule. The cost savings would be negligible, especially when compared to the cost of the machinery required to create the holes in the first place.

- Myth: They help dissipate heat. The surface area of the holes is far too small to have any meaningful impact on cooling the prongs. Electrical plugs are designed to operate well within safe temperature limits without such features.

So Why Don't All Plugs Have Them?

You may have noticed that not every plug has these holes. As electrical standards and manufacturing techniques have evolved, so have plug designs. Many modern outlets provide sufficient tension without needing the holes to grip the prongs. Furthermore, some manufacturers have developed alternative methods for securing prongs during the molding process. The holes are a common and effective feature, but they are not a mandatory requirement by the National Electrical Manufacturers Association (NEMA) for all Type A and B plugs.

Conclusion

Those small holes on your electrical plugs are a testament to thoughtful, multi-purpose design. Their primary function is to provide a secure grip inside the outlet, ensuring a safe and reliable connection that prevents plugs from becoming dangerously loose. Secondarily, they serve as a practical aid during the manufacturing process, helping to create a well-constructed final product.

It’s a simple solution to a simple problem, but one that enhances the safety and functionality of a device we use every single day. So the next time you plug something in, take a moment to appreciate the subtle engineering at your fingertips—a small detail that makes a big difference.