Why does rubbing two pieces of styrofoam together produce such a loud, jarring squeak

That skin-crawling squeal isn't just friction—it's a microscopic, high-speed battle of 'stick-and-slip' that generates one of the most jarring sounds known to the human ear.

Too Long; Didn't Read

TLDR: The squeak is caused by stick-slip friction. The tiny beads on the Styrofoam surfaces catch and suddenly release thousands of times per second, creating high-frequency vibrations that its structure amplifies into a loud, jarring sound.

Unpacking the Noise: Why Does Rubbing Two Pieces of Styrofoam Together Produce Such a Loud, Jarring Squeak?

We’ve all been there. You’re unboxing a new television or appliance, and as you slide the protective packaging apart, you’re hit with it: a high-pitched, teeth-grinding squeak that seems to vibrate through your entire skull. It’s a sound that is universally recognized and, for many, universally disliked. But have you ever stopped to wonder what’s actually happening on a microscopic level to produce such a uniquely jarring noise? The answer isn't just simple friction; it's a fascinating combination of material science, physics, and acoustics. This post will break down the science behind the shriek, revealing how a seemingly simple material creates such a complex and powerful sound.

The Anatomy of Styrofoam

Before we can understand the sound, we need to understand the material. What we commonly call "Styrofoam" is technically Expanded Polystyrene (EPS). It's created by expanding tiny polystyrene beads with steam, fusing them together into a block. The result is a material that is surprisingly complex.

- Mostly Air: EPS is about 98% air. This air is trapped inside millions of tiny, thin-walled, and rigid plastic cells.

- Rigid Structure: Unlike a soft sponge, the walls of these polystyrene cells are hard and stiff.

- Bumpy Surface: On a microscopic level, the surface of EPS is not smooth but a landscape of these fused, bumpy beads.

This unique structure—a rigid, bumpy surface made of a vast network of tiny, air-filled chambers—is the perfect stage for the sound to be born and amplified.

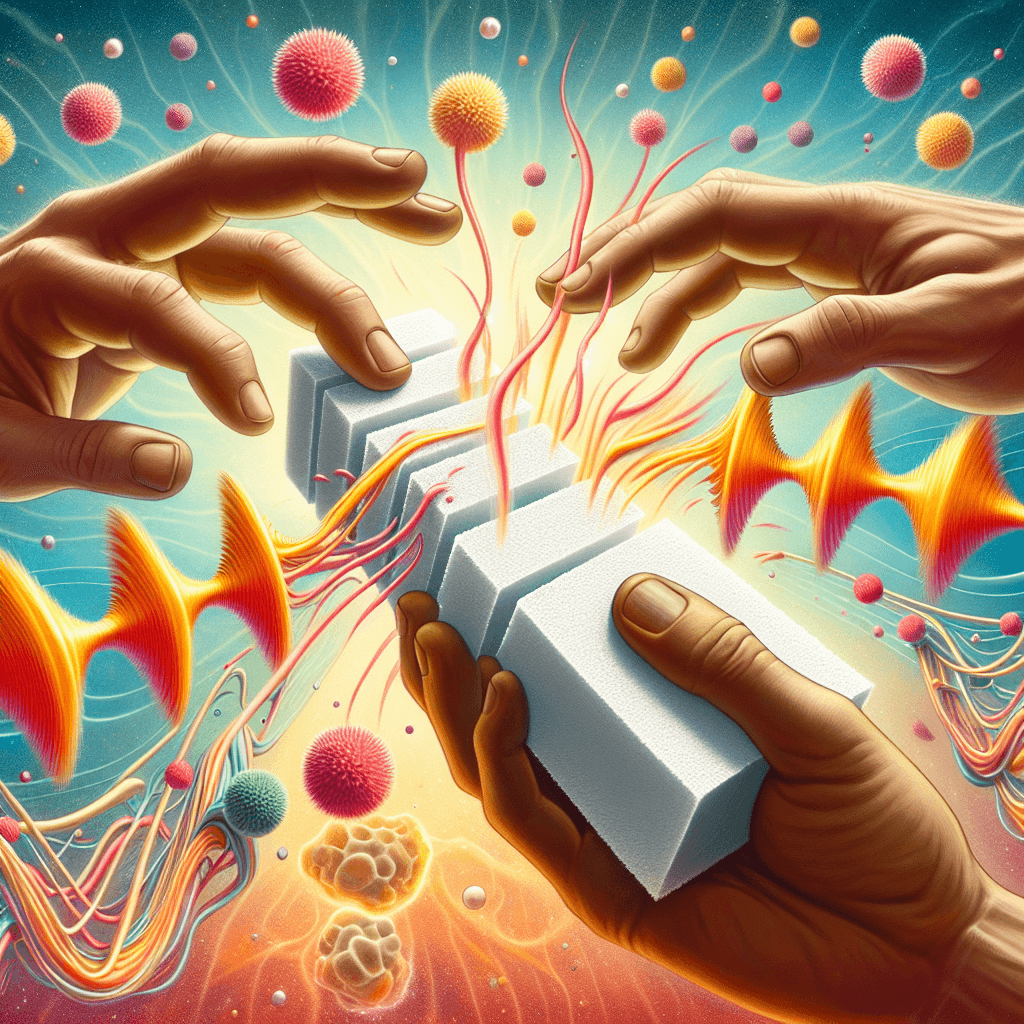

The Physics of the Squeak: Stick-Slip Friction

The core mechanism behind the squeak is a phenomenon known as stick-slip friction. It’s the same principle that causes a violin bow to make a string sing or car tires to screech on the pavement. It’s not a smooth, continuous slide but a rapid, stuttering series of movements.

Here’s how it works with styrofoam:

- Stick: As you press two pieces of EPS together and try to slide them, the countless microscopic bumps and ridges on their surfaces interlock and catch on each other. For a brief moment, they "stick" together, and the surfaces resist movement.

- Slip: As you continue to apply force, tension builds up. Eventually, the force becomes strong enough to overcome the friction, and the interlocked bumps suddenly break free and "slip" a tiny distance.

- Repeat: As soon as they slip, they almost immediately catch on the next set of bumps, and the process repeats—stick, build pressure, slip, repeat.

This entire stick-slip cycle happens thousands of times per second, creating a high-frequency vibration. But a simple vibration isn't enough to produce that room-filling screech.

The Amplifier: How a Vibration Becomes a Roar

This is where the unique structure of EPS plays its most crucial role. The high-frequency vibrations created by the stick-slip friction travel from the surface into the body of the styrofoam. The vast, interconnected network of air-filled cells acts as a natural and highly effective acoustic amplifier.

Think of an acoustic guitar. When you pluck a string, the vibration itself is quiet. It's the hollow wooden body of the guitar that resonates with that vibration, amplifying the sound and giving it volume and tone. The styrofoam block functions in the same way. Each of the millions of tiny, rigid cells vibrates in response to the initial stick-slip action, causing the trapped air inside to vibrate as well. This collective resonance turns a tiny, high-frequency vibration into a loud, penetrating sound.

The rigidity of the polystyrene plastic is what makes the sound so high-pitched. Softer, more flexible materials would absorb the vibrations, dampening the sound. But because polystyrene is hard, it transmits these vibrations efficiently, resulting in that signature high-frequency squeal.

Conclusion: The Perfect Sonic Storm

The cringe-inducing squeak of styrofoam isn't just a random noise; it's the result of a perfect sonic storm. It begins with the microscopic, high-speed stuttering of stick-slip friction between two bumpy surfaces. This creates a high-frequency vibration that is then captured and dramatically amplified by the material's unique structure—a rigid, air-filled matrix that acts like a massive soundboard. The final result is a loud, high-pitched, and jarring sound that our brains are almost hardwired to find unpleasant. So, the next time you unbox a new gadget and hear that infamous shriek, you can appreciate the intricate physics at play, even as you reach to cover your ears.