Why is there fake stitching molded into some car dashboards

That premium stitched leather on your dashboard might just be a clever plastic illusion. Discover the surprising psychological reason automakers use this trick to make you perceive luxury.

Too Long; Didn't Read

TLDR: It is a cheap manufacturing shortcut to make a plastic dashboard look like more expensive, hand-stitched leather, giving a budget interior a more premium feel.

The Detail in the Dashboard: Why Is There Fake Stitching Molded into Some Car Dashboards?

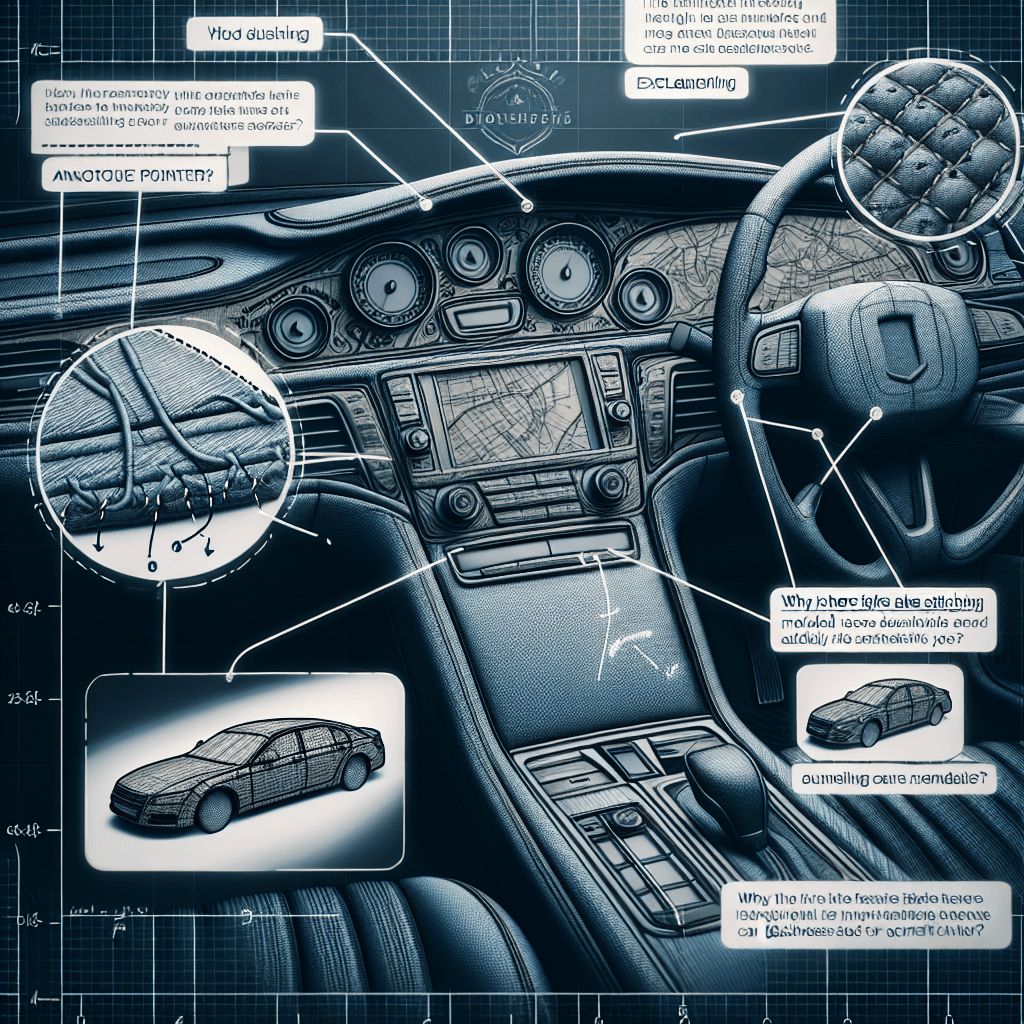

Have you ever settled into a new car, run your hand over the dashboard, and noticed something a little… off? The stitching looks perfect, almost too perfect. The lines are flawless, the spacing is mathematically precise, and the texture feels more like plastic than thread. That’s because, in many modern vehicles, it is plastic. This molded-in fake stitching has become a common design feature, leaving many to wonder why manufacturers go to the trouble of imitating a detail they could simply leave out. This blog post delves into the fascinating intersection of cost, psychology, and manufacturing to explain the real reasons behind the automotive world's most convincing illusion.

The Allure of Luxury: Aspiration Meets Affordability

At its core, the use of fake stitching is about aspirational design. Genuine, hand-stitched leather dashboards are a hallmark of true luxury. They are found in high-end vehicles from brands like Bentley, Rolls-Royce, and top-tier models from Mercedes-Benz and BMW. This feature signifies craftsmanship, attention to detail, and a significant investment in both time and expensive materials.

For the average car buyer, a hand-stitched dashboard is financially out of reach. However, the desire for that premium feel is universal. Automakers understand this powerful psychological driver. By molding fake stitching into the vinyl or soft-touch plastic of a dashboard, they can evoke the look and feel of a luxury vehicle at a tiny fraction of the cost. It’s a visual shortcut that elevates the entire cabin, making an economy or mid-range car feel more sophisticated and upmarket than its price tag might suggest. This allows consumers to experience a piece of the luxury world without the associated expense.

The Economics of Manufacturing: Cost vs. Perception

The decision to use molded stitching is heavily rooted in the economics of mass production. Let's break down the key factors:

- Cost-Effectiveness: The cost difference between a genuine stitched leather dashboard and a molded plastic one is staggering. The former involves expensive hides, skilled labor, and a time-consuming assembly process. The latter is created through injection molding, where a single mold imprints the texture, grain, and "stitching" onto a piece of plastic in seconds. This process is highly automated, repeatable, and incredibly cheap at scale.

- Consistency and Quality Control: Human hands, no matter how skilled, are not perfect. Achieving perfectly uniform stitching across hundreds of thousands of vehicles is a major quality control challenge. Molded stitching, on the other hand, is flawless every single time. The pattern is digitized and etched into the mold, ensuring that every dashboard that comes off the assembly line is identical. This eliminates defects and streamlines production.

- Design Flexibility: Creating a mold is a one-time investment. Once it's made, manufacturers can produce millions of identical parts. This process also allows designers to experiment with complex patterns and placements that might be too difficult or expensive to achieve with real thread.

Durability and Safety in Modern Materials

Beyond aesthetics and cost, there are practical engineering reasons for choosing molded dashboards. The materials used in modern car interiors are highly advanced and chosen for specific performance characteristics that genuine leather often lacks.

Modern dashboard materials, typically vinyls or thermoplastic olefins (TPOs), offer superior durability. They are engineered to withstand decades of exposure to harsh UV rays without fading and extreme temperature fluctuations without cracking. Unlike real leather, which requires regular cleaning and conditioning to prevent it from drying out, these synthetic materials are virtually maintenance-free.

Most importantly, dashboards are a critical safety component. They are designed to work in precise concert with the passenger-side airbag. During a deployment, the airbag bursts through a pre-weakened seam in the dashboard. A solid, molded piece of material is engineered to tear open in a highly predictable and safe manner. A dashboard wrapped in real leather with genuine stitching introduces more variables, potentially interfering with the optimal deployment of the airbag.

Conclusion: A Clever Piece of Engineering

So, the next time you encounter fake stitching in a car, don't dismiss it as a cheap trick. Instead, see it for what it is: a sophisticated piece of design and engineering. It represents a clever compromise that delivers a premium aesthetic to the masses, driven by the realities of manufacturing economics and the practical demands of durability and safety. This small, often-overlooked detail is a perfect example of how modern automakers skillfully balance our desire for luxury with the necessity of affordable, reliable, and safe transportation. It’s not just fake stitching; it’s the democratization of design.